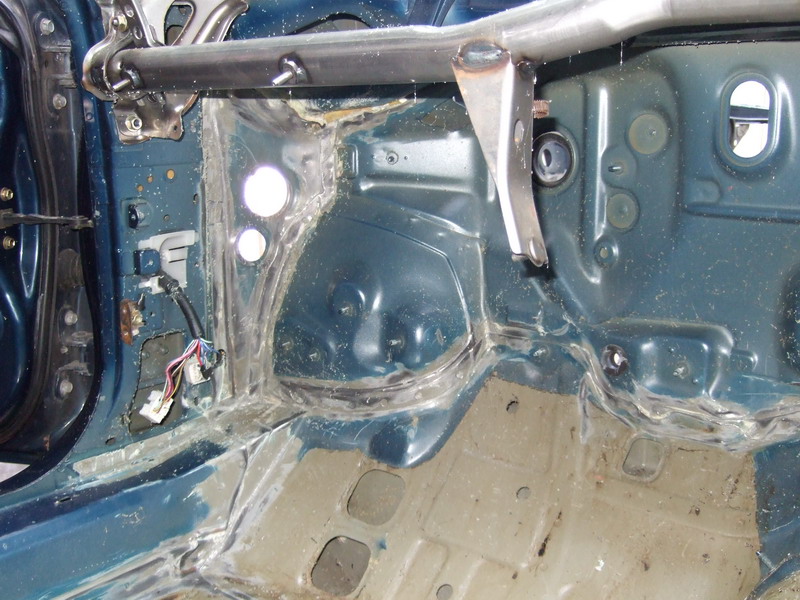

Some pics showing the latest progress with the chassis. The beige coloured parts of the shell indicate the areas where the sound deadening material has been removed The fuel tank, brake and fuel lines have also been removed. All the sealer has been removed from the spot welded chassis joins in readiness for seam welding. Even although the roll cage will take most of the suspension loads stiffening the shell in this fashion should help make the handling more precise.