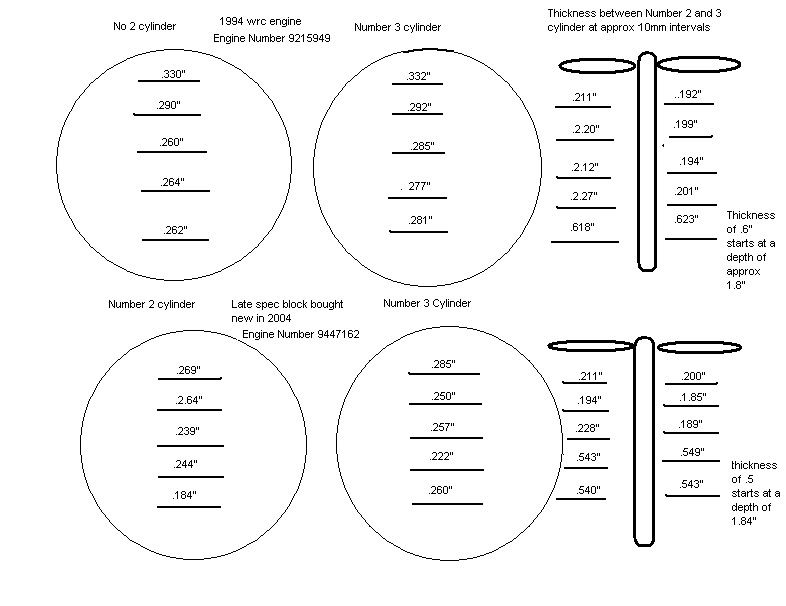

after my block cracked i decided to invest in a ultrasonic thickness gauge to allow me to measure the thickness of these so called thin, thick wall blocks to see if there was a difference in my block.

i measured two blocks 1 1994 wrc block and a 2004 Toyota bought block and the results were almost identical, there is no noticeable difference, if anything the 1994 block is ever so slightly thicker !!!!!

I still think there many of been a batch of early blocks with issues but i don’t think for a second this is epidemic to all early blocks i think this affect very few blocks, ive certainly only seen two blocks in all of the 3s-gte engines ive rebuilt that i would term to have had manufacturing inadequacies that caused them to fail

hence the reason i am 99% convinced my failure was due to distortion.

the results from the small test i did are below.

i have currently sent off a block to a specialist company who test bed blocks for manufacturers, i am getting them to do cylinder wall distortion mapping, and basically destroy the block to see if they can figure out were the weak points lie.

£4000 later i just hope they don’t come back to me and say sorry, the block is inherently floored and there’s no way of reliably running big power through this engine.

i will keep anyone interested in there findings informed, and hopefully we will find a definitive answer and solution.