Bit of theory first.

An electrical circuit can be likened to a water system. You have 'current' which will be constant through the whole circuit. If it splits into 2, then the current at the combined part will be the sum of the current of the individual branches. Voltage equates to 'pressure' and effectively represents the force pushing the current along. If you measure the voltage drop across each element of a series circuit, then the sum is equal to the voltage across the whole circuit. Resistance is a measure of how hard you need to push to get a certain flow.

V (volts) = I (amps) x R (resistance)

P (watts) = I x V = I squared x R = V squared / R

If we take a car lighting circuit, the filament in the bulb is designed to have the correct resistance to draw the required current for the power required. A 12V 60W bulb will draw 5A (I = P / V) at 12V. If we have 2 in paralell (12V on each) then the total current draw into the circuit is 10A.

The wire and connectors normally have a very low resistance and is normally assumed to be 0 in calculations. In practice, all wire has resistance and therefore some voltage will be dropped across it. e.g. total wire resistance of 0.1ohm will drop 1V at 10A, leaving 11V across the lights resulting in less light out, plus power of 10W lost in the wiring which manifests in the form of heat.

As can be seen from the equations above, the greater the resistance, the greater the volt drop and the greater the heat.

So if you have an intermittant problem with a circuit, where do you start looking, assuming you can't replicate the fault in the workshop where you can start diagnosing with a meter.

'Break' faults along wire runs are rare as the wire is copper (normally) which tends not to corrode very deep. Copper does work harden, becoming brittle and then breaking, but this requires a lot of regular movement with the multi-stranded type normally used in automotive applications. The 'solid core' stuff normally used in fixed domestic installations is far more prone to this and should be avoided for automotive use. Soldering also makes wire much more brittle and should be avoided unless the wire is supported near the joint to prevent any flexing of the joint.

The type of fault that is more common along the wire length is where a loom or wire is run over an edge which then wears through the insulation. This is common with aftermarket wiring, or where looms have not been attached as per OEM. This type of fault normally results in fuses blowing intermittantly, so this is the first think to look at if blown fuses is the problem.

Most 'break' faults occur at junctions, or wire ends. Most automotive connectors are 'crimp type' as these don't make wire brittle and are also quicker and less skilled to make. They do, however, suffer more from corrosion in the damp environment as the voids between wire strands are not sealed. The corrosion is non-conductive and as it builds up, starts to isolate strands at the point of connection increasing resistance. As the resistance builts, the joint starts to get hot which accelerates the rate of corrosion and failure follows quickly.

So the first thing to look for is evidence of heating at all the wire joins, fuses etc. In the early stages, this may be discoloration of the plastic or wire insulation. With aftermarket insulated crimps, the marks left by the crimp tool will disappear and the plastic will start to 'shrink' and turn brown. Also check for frayed strands of wire, especially on soldered joints.

A few examples.

Crimp on blue wire starting to show first signs:

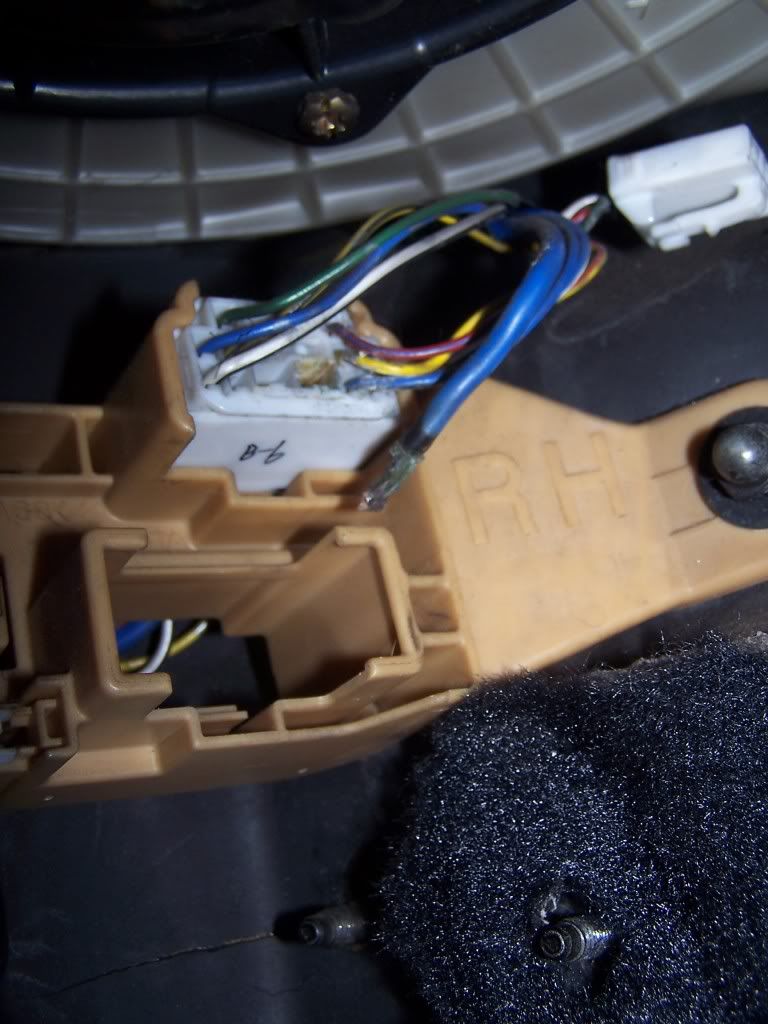

Bad pin in a multi pin connector after removal. Note blackening of wire insulation at end, and brown colour of the connector body.

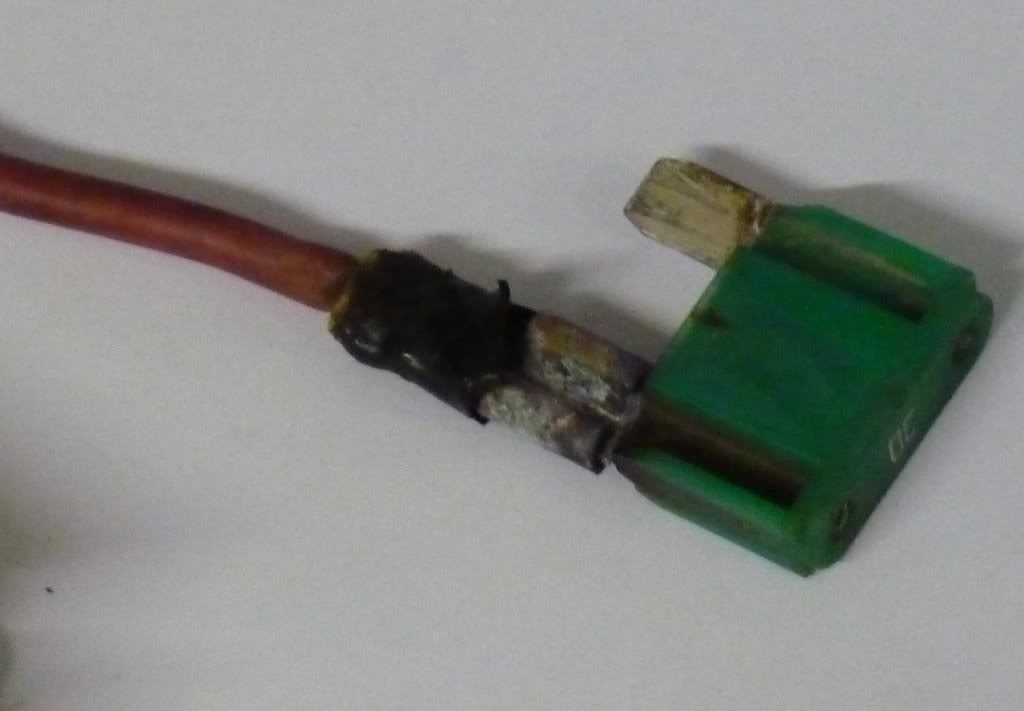

Note slight deforming of wire insulation by crimp, blackening of fuse & corrosion visible on connection. Insulating tape round crimp had also gone hard & melted into crimp.

A bit more extreme. Battery charger was showing a charging fault and vehicle was very sluggish (one of our electric vehicles). Wire just fell off when I touched it.

_________________

If at first you don't suck seed, try drier grain.